In terms of management, some organisations are still in their ‘comfort zone’. They tackle issues the way they have always done, because basically… that’s just the way they do it. As long as that accounts for the desired results and works for the team: fine. But what if a problem or matter comes their way that cannot be solved with their current way of working? Time for a different approach!

Recently, our colleague project lead and Lean Sigma Black Belt Frank van Laarhoven got to work on a project at Thomas Regout International. This factory in Maastricht, which mainly produces telescopic slides, is in need of a new machine. But there is simply no room for it. A matter of tidying up and creating space you might say, but that is easier said than done. Put 1 or 2 things in a different place, and you might disrupt the entire process chain of one of your colleagues in another department.

Inventory

To find a sustainable solution for optimising floor stock, Frank started by taking stock of the current situation using the DMAIC cycle. In this, he included not only his own findings, but also those of colleagues. A group of operators, planners, team leaders and engineers identified the potential impeding factors on the shop floor using the Ishikawa (fishbone) diagram through several sessions. Using these first three phases, Define, Measure and Analyse, the main factors could be analysed.

The main ‘bottleneck’ in the process turned out to be the fact that the quantities of strip steel were not aligned with the actual planning of orders. Calculations of the actual number of coils needed were also not sharp enough, which in turn resulted in leftovers remaining on the shop floor. To give you an idea: by now, there was over 10 days’ worth of unused material on work floor. And what a coincidence: it was exactly the amount of space the company needed for its new machine…

Creating space

Now that the cause of the problem was clear, Frank and his team could get to work on the Improve phase. To tackle the quantities of coils, Frank figured it would be better to deliver the required strip steel using the existing planning tool and place at the right machine, and in the right order. This way, everything is within reach for porduction, which reduces the lead time and avoids unnecessary materials left standing. Besides the smarter use of orders , Frank has also already thought about how to label the coils and the racks on which they are placed. Using QR codes, these can later be scanned and a colleague can see the destination of the material at a glance. This way, everything should be running smoothly and quickly, and avoid putting things in the wrong place.

LEAN: a new mindset

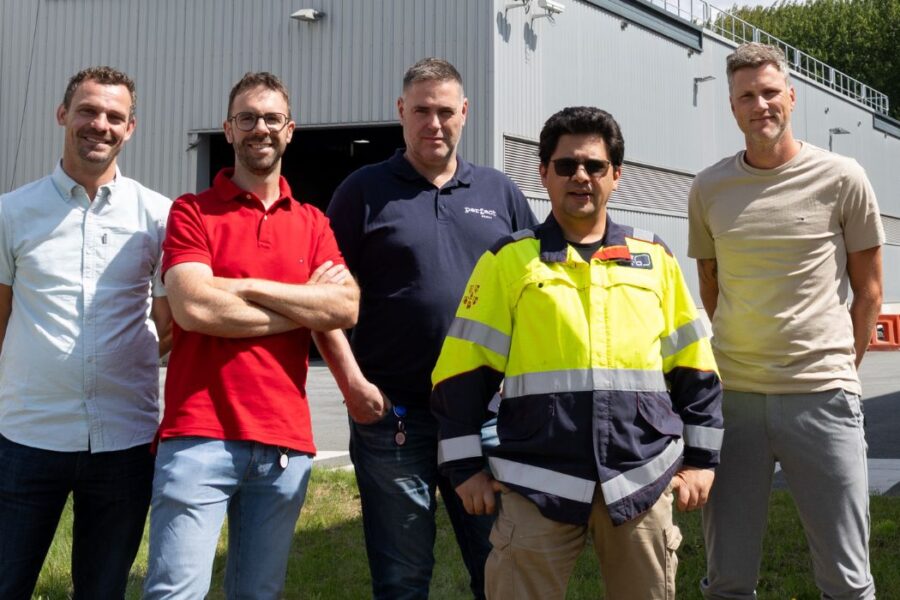

Frank’s innovative plans have now been presented to the team and are about to be rolled out. Although the new way of working requires a different mindset from the employees, his kick-off was enthusiastically received. In addition, a number of employees have received training from the Perfact LSS Academy to become Green Belt through the LCS accredited curriculum. This way they will soon be able to apply Frank’s plan seamlessly on the work floor. In addition to Frank, employees are supported by Director of Operations, and also black belt, Daniel Kappes and coached by Perfact’s Bas Mooij, master black belt.

Although the Lean method is now mainly focused on creating space for the machine, it will also find its way into other processes and operations at Thomas Regout International. “Traditional management mainly consists of putting out fires,” Frank explains. “If there was a problem, you looked for a solution that you could move forward with at that moment, focusing on a short term solution. By teaching employees how to tackle such issues the Lean way, you come up with solutions that apply for the longer term. That saves a lot of recurring problems and works a lot more efficiently”.

Does it take a lot of getting used to, this switch in mindset and way of working? “No, not really,” says Frank. “Lean is not a new concept here – Daniel Kappes is a black belt and a number of issues were already being addressed using this method. Colleagues definitely see the added value of it. Indeed, besides creating space for a new machine, we shorten lead times and, by working more efficiently, as well as reducing the workload. That’s win-win for everyone!”