If an organisation focuses on Business Excellence, it is constantly optimising, improving and changing in order to keep working towards its objectives. The challenge here is not to keep to your own ‘island’: after all, successes need to be made across all the aspects of a company, not just in a specific department. However, this requires a good internal approach that looks beyond just the maintenance or engineering discipline.

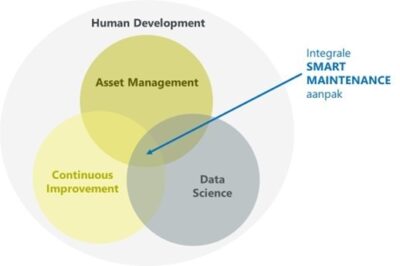

In our view, the integration of Lean Six Sigma and Smart Maintenance within asset management can be of great help here. Indeed, these encourage cross-functional collaboration between maintenance, operations and quality teams – which in turn ensures better decision-making and problem-solving.

The goal of asset management is to control risks and manage the optimal use of capital-intensive assets. This discipline ensures that assets remain at an optimal level, but is not primarily focused on improving business performance. Nowadays, we see an increasing amount of data being produced around asset management and production processes; however, it is rarely used to its full potential.

Smart Maintenance

At Perfact, we specialise in applying improvement methodologies in various business processes. We have found that achieving ‘business excellence’ has a lot in common with the field of Smart Maintenance.

Maurice Jilderda, our Business Development Manager knows all about this. “Especially when customisation is involved, the ingredients for success are very diverse and require a thorough and integral improvement approach,” says Maurice. “Whether the question is about smart maintenance or another topic, we always start by forming a complete picture: where the company wants to go, what objectives there are and which initiatives are already up and running. We then take the well-known five steps of Lean 6 Sigma in the form of DMAIC – Define, Measure, Analyse, Improve and Control. We also look at whether adding the elements such as data science and coaching can provide additional impact.”

The outcome of the analysis phase may be that Smart Maintenance becomes an important part of the roadmap, but this is not always the case. It happens that much more interesting improvements are found in other areas to achieve business goals.

“I’ll have one of those industry 4.0 solutions, please”

Increasing intelligence with your data and asset management is something many companies still struggle with. Sure, they know how valuable it can be but where do you start? Last year, for instance, we were asked to implement an industry 4.0 solution. The first question then is: what exactly do you have in mind, and for what purpose? After an initial quick scan, we were advised to start by optimising the logistics processes, because that turned out to have a lot to gain. In addition, the maintenance department turned out not to be mature enough to implement advanced techniques and would not come close to the proposed improvements in terms of added value anyway. So you see, Industry 4.0 does not happen overnight.

So smart maintenance, and especially scans, always adds its value. We have never seen a plant or company where no improvement potential could be found. Smart maintenance also usually fits well into the overall roadmap, but the priority and timeline can be different between them. In any case, awareness and being open to new developments are already a nice first step in the right direction!